Sicily is at the top in world production for peculiar characteristics

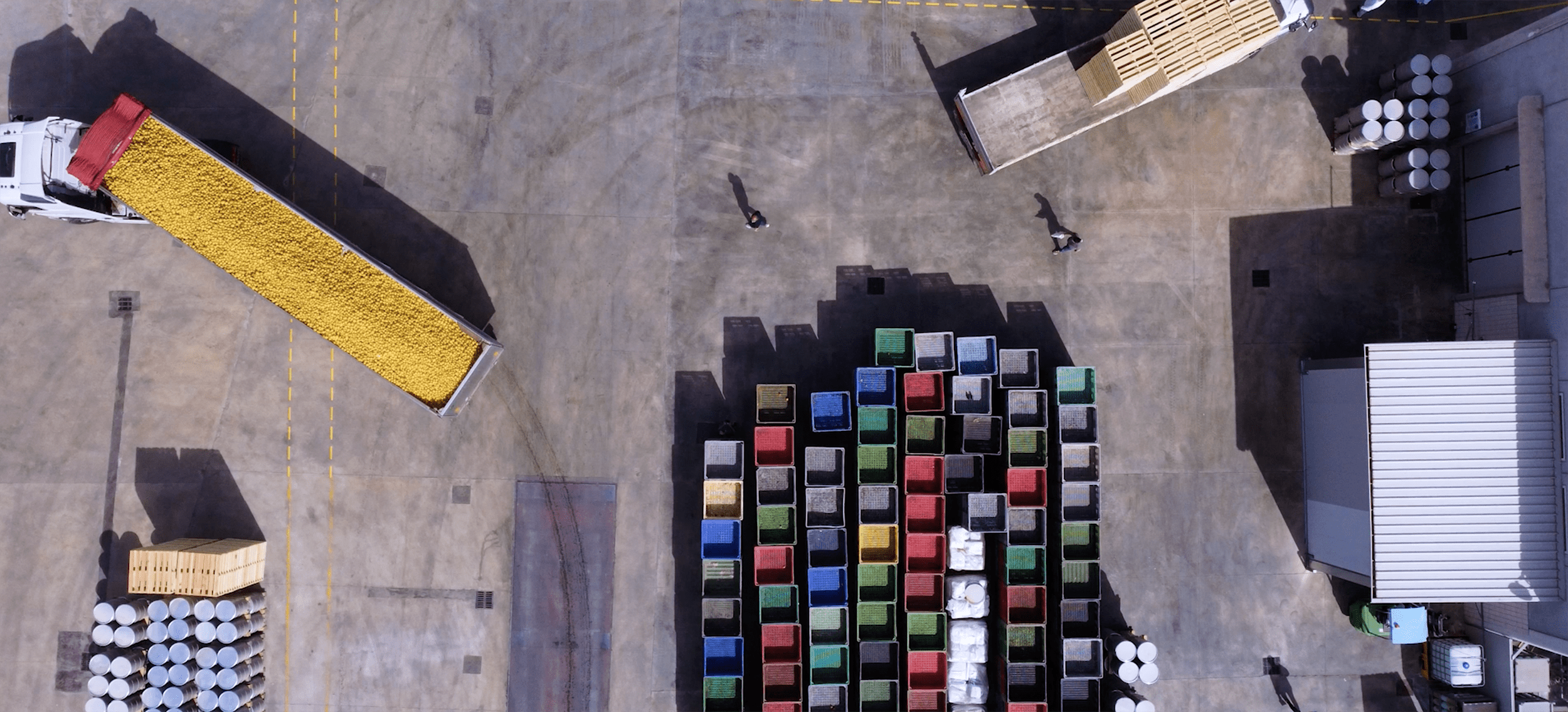

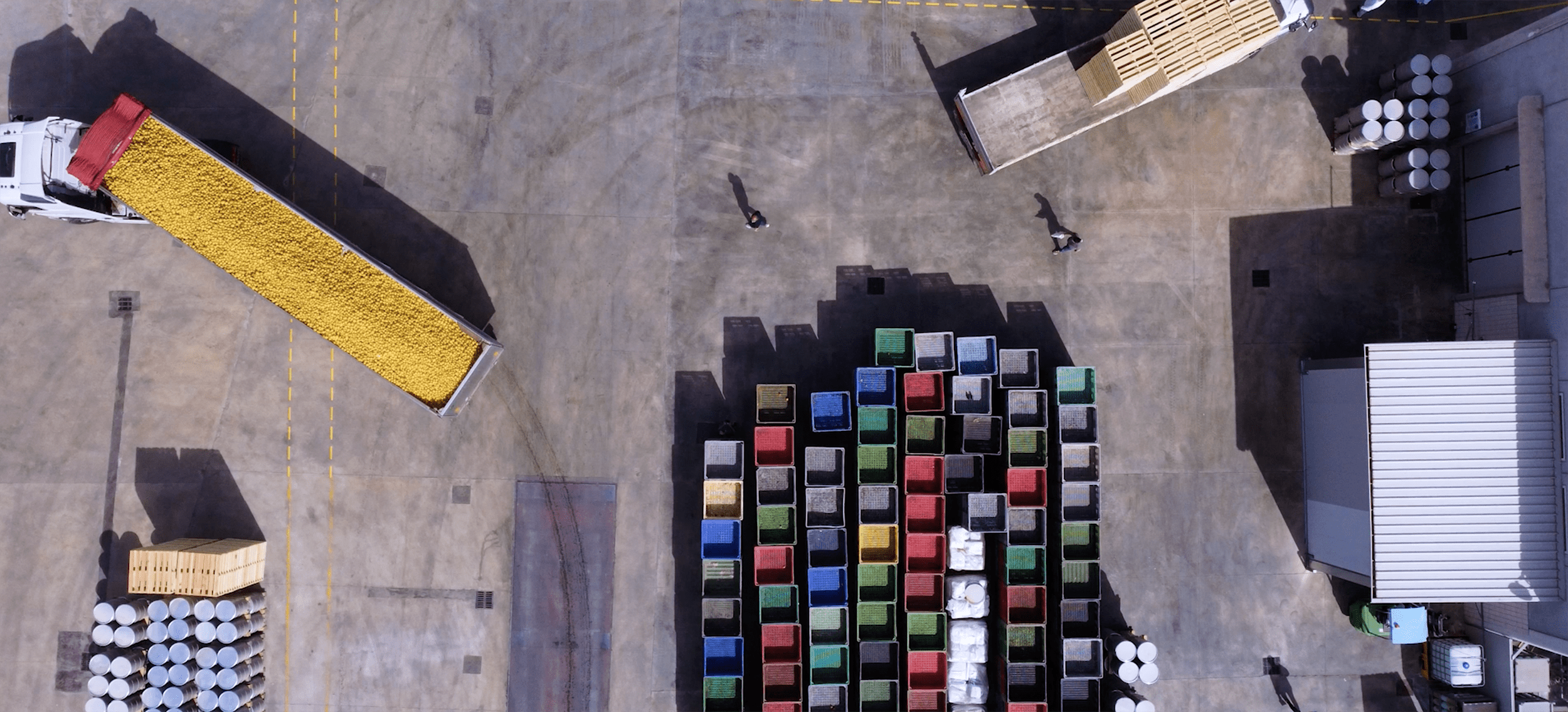

We create an extensive range of customized fruit-based solutions

Technology and know-how to meet the client's needs

- Aim for excellence

Over 50 years of experience

Citrofood is a trusted partner for important customers leaders in various industries, including juices, nectars, beverages, soft drinks, breakfast products, dressings, bases for ice cream and pastries, flavorings, cosmetics, fragrances and pharmaceutical products.

Roughly 80% of the Italian citrus production is located in Sicily.

Trusted by hundreds of companies worldwide

OUR PLANET. OUR FUTURE.

Citrofood strongly believes in a sustainable cycle. For many years now, the company has been processing sustainable specialties that use around 85% of the fruit.

- Juices and essential oils

Our Products

- 2 connected buildings

Business Continuity

In the event of an emergency, thanks to its successful partnerships built over decades, Citrofood is able to ensure continuity of its supply via an independent facility in the area that is full certified and in compliance with current Food Defense requirements.